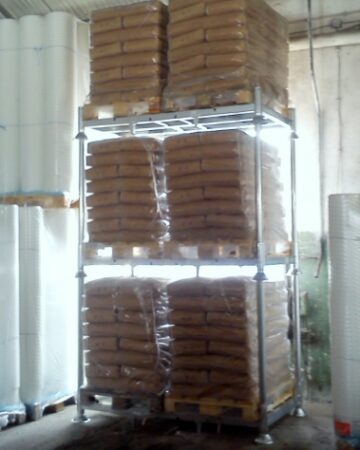

Inefficient use of storage

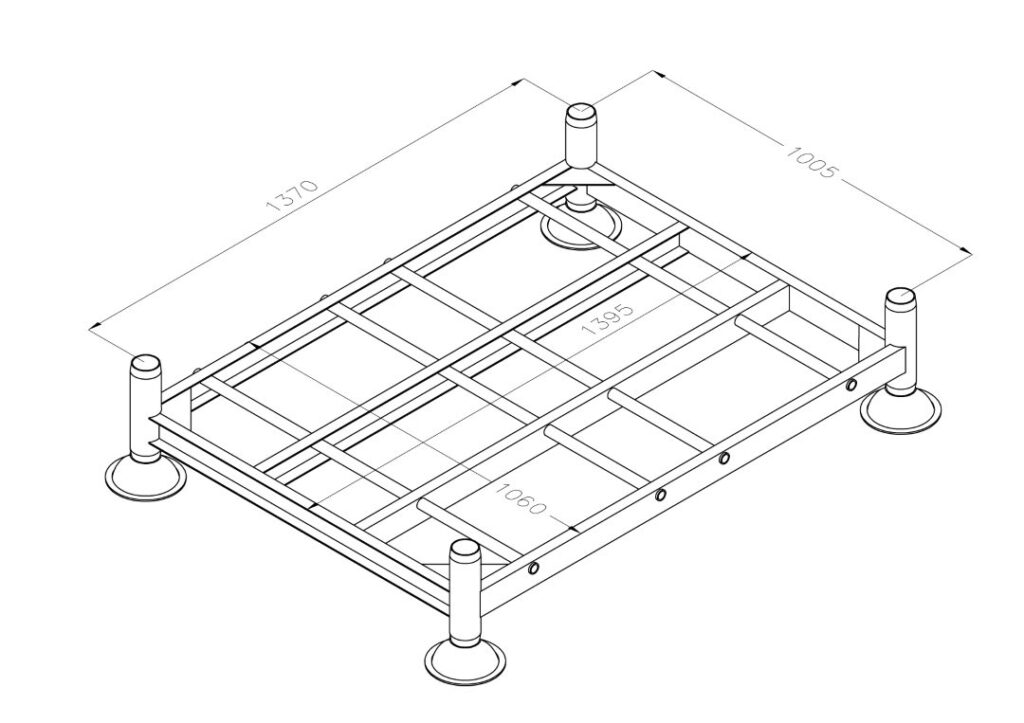

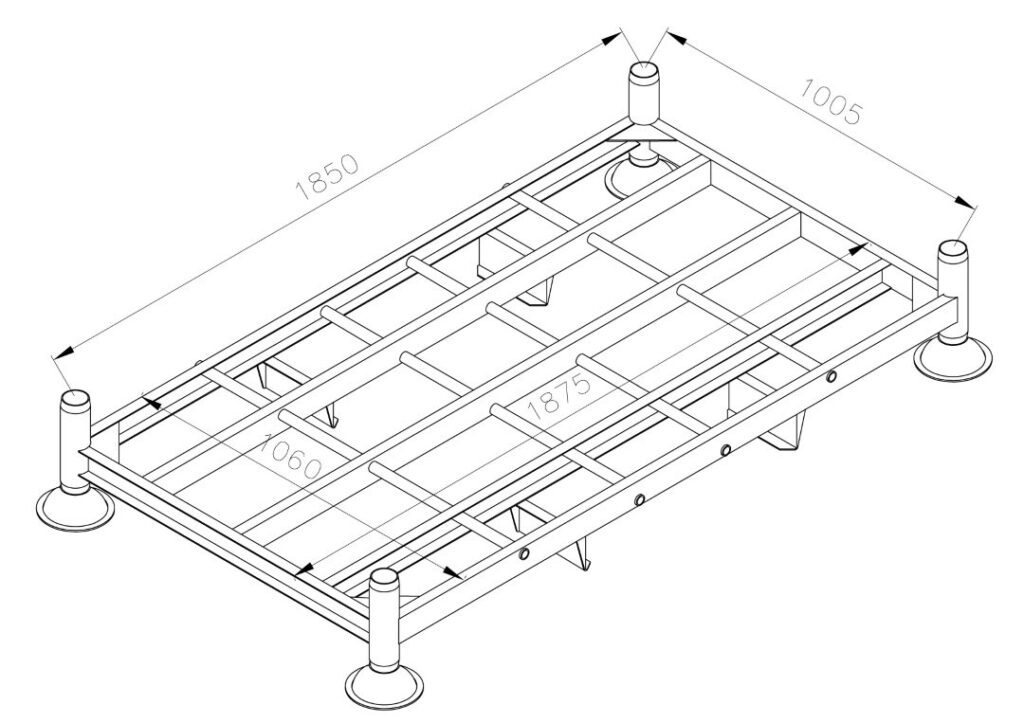

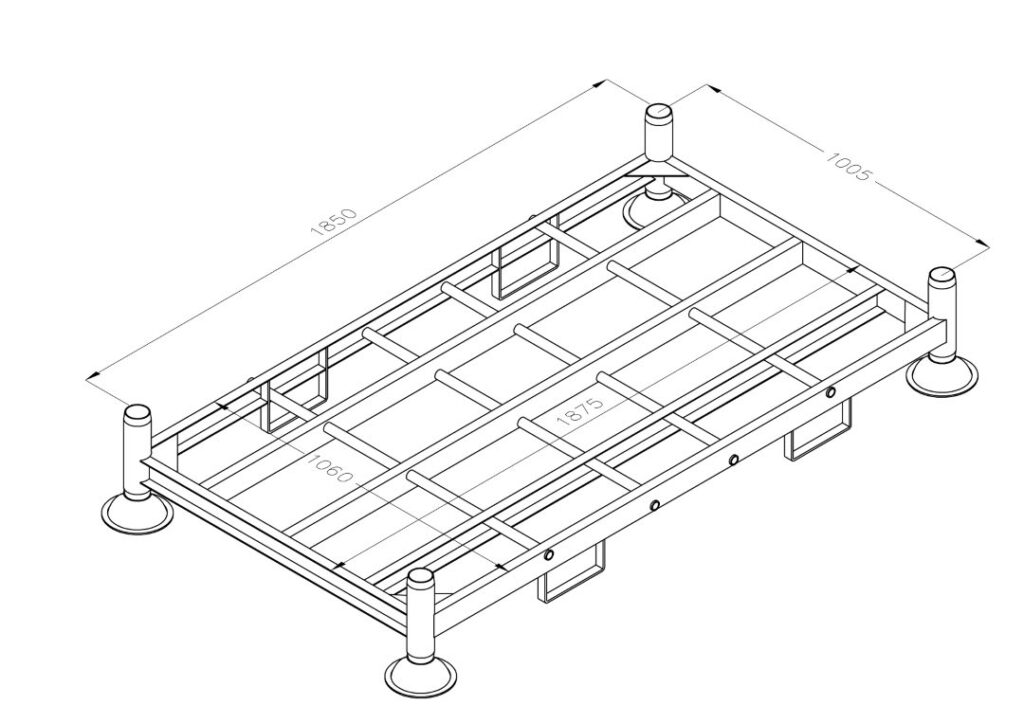

Very often goods stored on traditional “Euro” pallets or in crates or cartons may occupy only the surface of the floor. Because of their weight or specific conditions, goods can not be arranged one pallet on the other. Huge amount of vertical space is wasted.“Manurack” pallets definitely improve the efficiency of warehouse space. The use of stacking enables to store in the same area up to four times more goods! Using a vertical tubes in a simple way we can arrange pallet into stack regardless of the stored cargo type. Other pallet types impermanence – Operations performed using a forklift often cause damage to wooden pallets. Stored goods, as well as warehouse workers may suffer from that. In both cases, the warehouse owner are liable to incur considerable expenditure.Also, storage conditions may shorten wooden pallets life – too wet / dry air, too low / high temperature, sunlight – that’s all (but not only) enemies of wood. On the other hand, some chemicals are enemies of plastics that certain types of pallets are made of. “Manurack” pallets are not indestructible, but made of steel, galvanized or powder coated can survive in harsh conditions for years. Their strength tests had confirmed an independent testing body: TUV Rheinland.